Working with Charah Solutions, you gain access to a full line of the highest quality industrial raw materials globally sourced to provide you with the optimum performance that your facility and operations demand. We understand that the industrial raw materials you use affect the quality of your final product, and the efficiency of your process. And we are dedicated to helping you achieve the sourcing, the scheduling and the technical assistance you need for the best possible results. Our lineup of industrial raw materials includes:

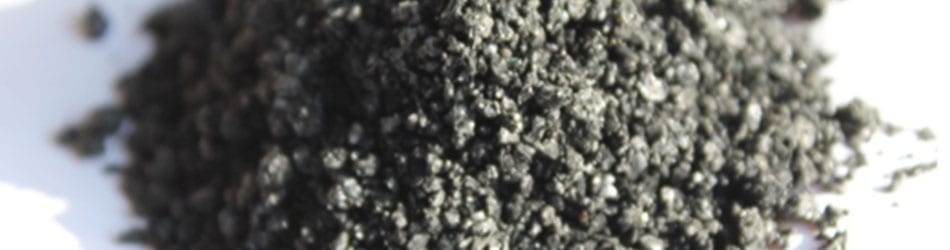

ABRASIVES

Abrasives are substances used to shape, smooth out or machine other gentler materials through extensive rubbing. Abrasive blasting is ideal for preparing any type of surface prior to repainting or re-coating, and it effectively removes old layers of paint and industrial coatings, and can also be used to remove corrosion, rust and other contaminants from many different types of materials and surfaces. Common high-quality recyclable abrasives include coal slag, copper slag, and other metallic grit.

APPLICATIONS:

Abrasives are used in many industries, from metal work to cleaning to wood-working. Common uses for abrasives include grinding, grinding down freshly cut metal (deburring), buffing, honing, cutting, drilling, polishing a finished product, etc.

ALUMINA SLAG

Alumina slag is very useful in manufacturing high alumina cements due to its high alumina content in the 85% range. Like other slag cements, alumina slag strengthens cement and makes it more resistant to chemicals. Alumina slag can also be used in other applications, such as the ceramics industry and for making high alumina refractory bricks.

APPLICATIONS:

Alumina slag is used to strengthen Portland cement, while making it more resistant to chemical agents, sulfates and sea water.

BAUXITE

Bauxite is a member of the chemical family: Metallic Hydroxide/Oxide. This is a naturally occurring sedimentary rock, non-chemically treated and contains one or more aluminum hydroxide minerals. The vast majority of all mined bauxite is used for aluminum metal manufacturing.

APPLICATIONS:

Bauxite is a rich source of aluminum as a raw material in the manufacture of Portland cement.

CLAY

Kaolin clay is a natural usually white or tan mineral (dioctahedral phyllosilicate clay), produced by the chemical weathering of aluminum silicate minerals like feldspar. It is widely used after calcining as a primary ingredient in the manufacture of China.

APPLICATIONS:

Kaolin clay adds favorable pozzolanic properties to Portland cement and can be used to increase its strength and increase resistance to sulfate attack, while decreasing corrosion and permeability and lightening the color of the finished concrete.

INDUSTRIAL SLAG

Industrial slag is a by-product of the copper smelting process. When in a molten state, the slag is quenched rapidly and washed by highly pressurized water. It is then granulated to create a black irregular shaped material that has a glossy appearance. Industrial slag has a very consistent chemistry and sizing. It handles well even when wet.

APPLICATIONS:

Industrial Slag can be used as an iron source in the manufacturing of Portland cement. Its benefits include an oil free source of iron oxide as well as a low chrome content. It is also a premier blasting abrasive.

IRON ORE

As a basic source of minerals from which metallic iron can be extracted, iron ore has many industrial uses. Iron ore is converted into various types of iron through several processes. The most common process is the use of a blast furnace to produce pig iron, which is further refined in a steel mill where it is combined with other elements to yield steel with specific steel properties.

APPLICATIONS:

The primary use of iron ore is in the production of iron, most of which is used in making steel, which has many applications.

IRON RICH MATERIALS (IRM)

IRM is a byproduct of a zinc recovery operation from the Waelz kiln process, which produces crude zinc-oxide, a raw material used in the production of zinc metal. The resulting IRM byproduct is cooled and discharged into a stockpile for shipment to our customers for use in manufacturing.

APPLICATIONS:

Iron source is ideal for cement manufacturing, steel manufacturing as well as asphalt/aggregate.

MILL SCALE

A byproduct of the steel manufacturing industry, mill scale has many industrial uses as a raw material. It consists of oxides of iron that form on the surface of hot metal during processing. While the steel is very hot, it picks up oxygen from the air and forms a thin crust. As the steel is stretched and shaped, the thin crust falls to the ground. It is very valuable as a metallurgical raw material as it contains high iron content.

APPLICATIONS:

Excellent for use as a raw material for manufacture of cement clinker, it can also can be used as a raw material in granular refractory applications.

NATURAL GYPSUM

Gypsum is a naturally occurring mineral mined in numerous locations throughout the world. Natural gypsum is chemically known as calcium sulphate dihydrate or CaSO4 2H2O, which is essentially the same chemical composition as synthetic gypsum.

APPLICATIONS:

Natural gypsum is mined as a natural raw material for use in building products such as drywall, cement additives and plaster. It is also used as a fertilizer and as the main constituent in blackboard/sidewalk chalk.

STEEL SLAG

Steel slag is a non-metallic byproduct of the steel making industry and consists of calcium, magnesium, aluminum and iron silicates. This slag Is formed when molten Iron, scrap metals and various fluxes, are oxidized by injecting large amounts of pure oxygen into the molten iron mix to create molten steel and molten slag. Slow cooling of the molten slag produces a dense rock material. With high particle density and hardness, Steel Slag has superior wear resistance – ideal for use as asphalt concrete.

APPLICATIONS:

Common applications for steel slag include blending with other products like granulated slag, fly ash and lime to form pavement material, including skid resistant asphalt aggregate, concrete aggregate, rail ballast asphaltic, soil conditioner and unconfined construction fill, granular base, engineered fill for embankments, highway shoulders and hot mix asphalt pavement.

SYNTHETIC GYPSUM

Synthetic gypsum is chemically manufactured gypsum and is generally considered a byproduct that is created during various manufacturing, industrial or chemical processes. It is important to note that synthetic gypsum and natural gypsum have essentially the same chemical compositions, both consisting predominantly of calcium sulfate dehydrate or CaSO4 2H2O. Synthetic gypsum is a process byproduct which reduces the need to mine natural deposits.

APPLICATIONS:

Like natural gypsum, synthetic gypsum is used in making building products such as drywall, cement additives and plaster.

SERVICE ABOVE ALL

With a proven global network and a broad base of expertise, we provide innovative sourcing, solutions, and technologies to keep you supplied with the raw materials and byproducts your industrial processes and applications need.

For more information about our international raw materials sales & services or to order materials, contact our global sales and support team at 877-314-7724.